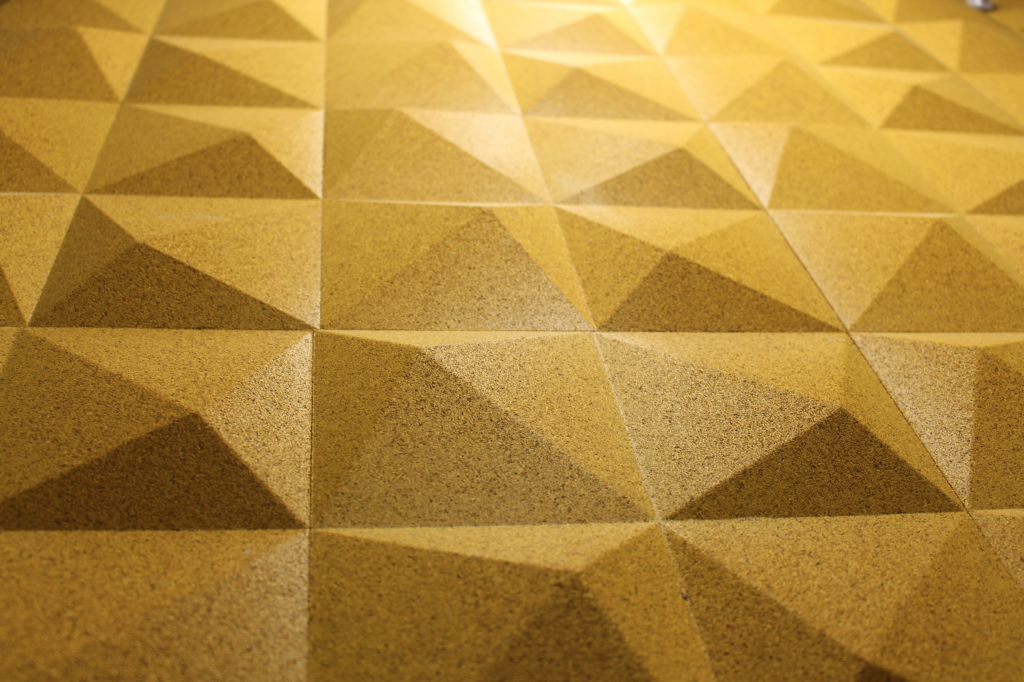

The bark of the cork oak can be removed every 10 years. The bark is processed by cooking and grinding it. Then, the material is subjected to three-dimensional cutting in different thicknesses and it is colored with a pigment. This results in a wallcovering made of 100% cork with unique esthetic and acoustic values.

These tiles consist of 100% cork

The production process

- The bark of the cork oak grows naturally and is removed from the tree once every ten years.

- The bark is then boiled and ground after drying so that it can be processed. The coloring of the cork is done with pigment.

- Cork is glued with the resin from the bark itself.

- The tiles can then again be ground to make new products.

By removing the bark, the tree can assimilate more CO2.

Applied

Cork is already being used in large numbers as a wall finish for both private and business clients. Cork is also used as a wall finish in schools and offices to improve the acoustics in the rooms.

Environmental impact

- By removing the bark, the tree is able to absorb more CO2 – which is better for the environment!

- For the processing of the cork, electricity is used that is produced by incinerating the (residual) waste cork.

- Cork is glued with the resin from the bark, so that a 100% natural product remains!

- The cork tile can be recycled in its entirety: it can be ground again to make new products. This means there is little to no waste from cork.

Also nice!

- Resilient

- Insulating

- Sound absorbing

- Anti allergenic

- Anti static