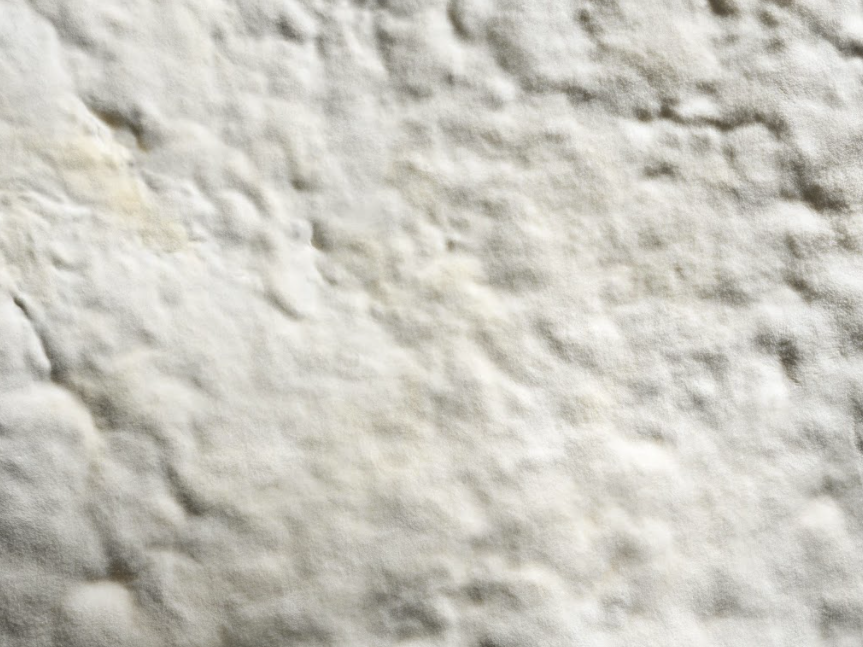

Mogu Acoustic tiles are certified products created by fermenting selected mycelium (the vegetative part of a fungus) on cotton residues deriving from the textile industry. The technical 3D modules include the models Kite, Wave, Fields and Plain, as functional solutions characterised by unique haptic qualities, and designed to maximise sound absorption and overall comfort in interior spaces.

Made from

Mogu Acoustic modules are made of soft, foam-like mycelium composite materials, relying on the valorization of upcycled textile residues through fungal fermentation. The tiles are biofabricated/produced by growing mycelium (the vegetative stage of mushrooms) on substrates composed of low-value residues which would otherwise be discarded (e.g. cotton fiber, hemp shives, etc.). The resulting products are 100% circular and biodegradable, with no use of petroleum-based binders, plastics or formaldehyde.

Production process

- First, cotton residues are sterilized and then inoculated with mycelium in bags to allow proper

growth and full colonization. - As the following step, the freshly grown material is grounded and laid in dedicated molds, where the mycelium keeps growing until it reaches the desired density/shape.

- Once the growth process is completed, the products are slowly dried and finished.

Applied

Mogu Acoustic modular panels are a perfect solution for any environment, elegantly fitting professional or residential landscapes with a beautiful, responsible and emotionally engaging functionality. They are designed as three-dimensional wall panels, easy to install, in 4 different shapes, to allow maximum design flexibility. Mogu Acoustic modular panels are provided with their own easy-to-mount and screwless fixing system.

Environmental impact

- Mogu Acoustic modules are made from 100% biobased, biodegradable materials.

- They are produced from soft, foam-like mycelium materials grown on upcycled textile residues.

- At the end of their life, Mogu Acoustic products can be entirely biodegraded, fully closing their life cycle loop.

Growth opportunities

Being a completely natural material, it can be sometimes difficult to fully standardize the related production process. Mogu, has established rigid protocols to allow a stable and consistent set of outcomes and they constantly run dedicated R&D campaigns to further improve our processes.

More info and contact

https://mogu.bio/