In The Netherlands, 180.000 tons of toilet paper is flushed on a yearly basis and burned as waste. Using a special technique, Recell Group filters cellulose from the drain and processes it into Recell. Recell is currently applied in constructions, agriculture and chemical industries – as additive, raw material or end product. Omlab 3D-prints with a paste composed of the circular residues cellulose, Kaumera and calcite.

Transforming sewage water into printed stone

The printing material is made of:

- 60% calcium carbonate from water softening treatment by Aquaminerals

- 5% cellulose is screened during sewage treatment process

- 5% kaumera and/or alginate obtained during the Nereda sewage treatment process

- 30% water

Production process of the building elements

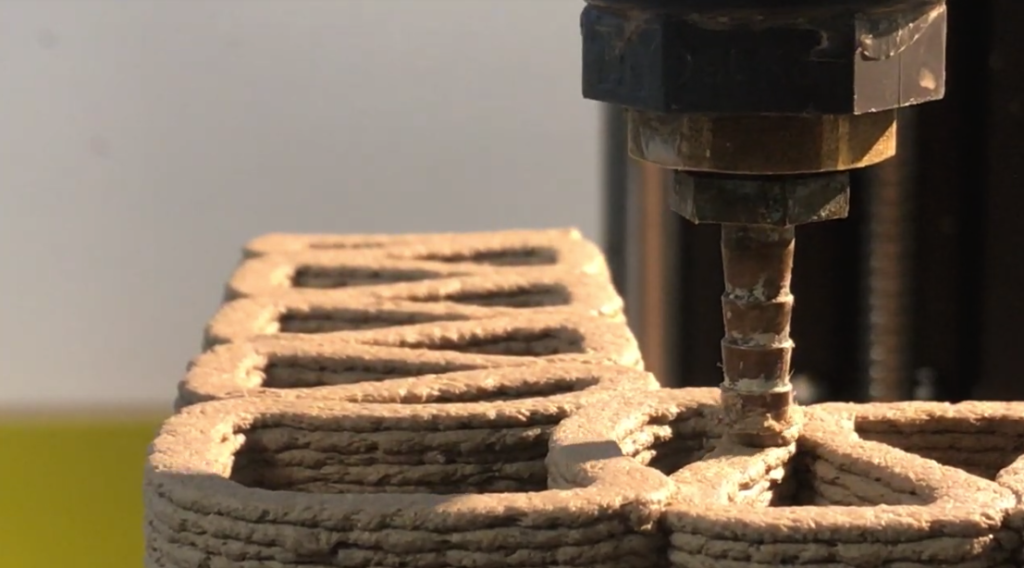

- The raw materials are mixed into a firm, clay-like paste, which is 3d-printed using an extrusion printhead.

- For printing the paste, it needs to be mixed and homogenized, this takes half an hour per half liter batch.

- The material is then printed (half an hour per liter).

- The material can receive post-treatment with calciumchlorate (5 minutes).

- Forced drying of the material, to harden the object, takes 1-2 days.

- The result is a breathing material that feels like stone or ceramic.

Applied

The toilet of The Exploded View is printed 1:4. But there are examples in which structures are printed 1:1. Check it out via the button below.

Environmental impact

- No nature-unfriendly materials

- Completely made out of residual flows from water treatment that were previously largely burned

- The material is not baked, and therefore regenerable

Health

The material is breathable and has a positive impact on the indoor climate. The printed shape allows extra ventilation.

Growth opportunities

This product is still being developed and awaiting test results. For large-scale production, more people, (companies that operate) larger printers and co-investors are needed.

Omlab started experimenting with adding colour to the material prototype. They wil showcase this at Coda Apeldoorn on July 3th 2021. At this moment the colours come from sewage treatment and drinking water production, which results into diffrent shades of grey. Recently they started using ocher for more colour shades. At the moment they are researching how to replace that colour by using a waste stream like pulvarized coal and coagulation slib.

In addition to that they are working on a weatherproof version of the material prototype.