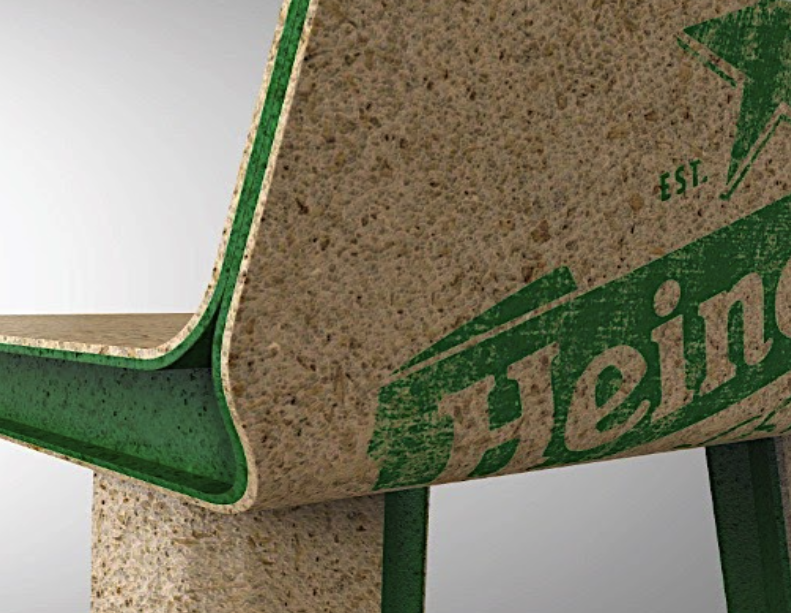

The fibers of the grains and hops that are used for brewing beer can be repurposed after the brewing process. ECOR uses residual beer grains from the Heineken brewery for their SBG panel, which is made of 25% beer grains and 75% recycled paper. Like any other ECOR panel, they are free from Volatile Organic Compounds, formaldehyde and other toxic chemicals.

The spent brewer’s grain panels are made of:

- 25% Spent Brewery Grains from the Heineken breweries’ process

- 75% Recycled Paper from a local facility in the Limburg region

The production process

- The production process depends on the residual materials streams used, the received raw material may need to undergo additional pre-treatment to extract the cellulose fibers.

- Once the fibers enter the process, only water is added to the mixture to make a wet panel at first.

- Then, with pressure and heat, the final ECOR panel is produced.

All ECOR panels are made from residual flows, with only the addition of water, pressure and heat.

Applied

The ECOR standard panels are developed to be applied in various ways: as marketing materials, packaging, interior design materials and/or building materials.

Environmental impact

- The ECOR panels have a clean production process, in which Volatile Organic Compounds and toxic glues are involved. Therefore, no heavy special environmental and discharge permits are needed.

- ECOR panels support circular business models or initiatives that maintain materials and products in use for as long as possible through, for instance, reuse, remanufacturing and repurposing.

- Zero waste production is fostered as the cutting losses from previous production becomes input for the next panels production, which can be both recycled and refurbished

- Valorize cellulose-based residual streams, which are sourced from bio-based feedstocks considered a waste material stream from e.g. harvesting or industry processes

- Contribute to a better and healthier world, phasing out waste