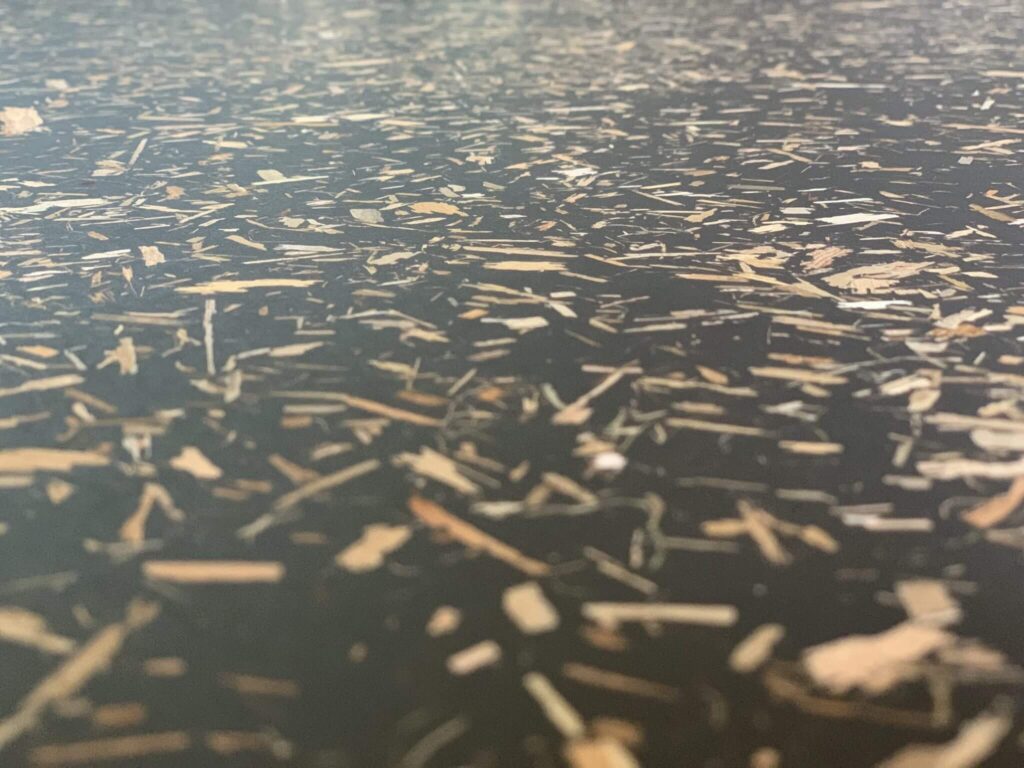

HuisVeendam develops products based on natural local fibers and starch. A main ingredient is cattail, also known as the ‘cigar plant’. This plant has a cleansing effect on the soil. Nature is embraced here by looking at which forces are present.

Made of

- Cattail

- Organic Fillers

- Jute

- Glue based on starch and organic fibers

Production Process

- Biolaminate consists of a jute surface. This is provided with a natural starch-based glue.

- Then small-cut plant remains such as cattail are spread over the glue.

- After a second layer of glue, the floorboards go into a press and are ready for use.

Environmental impact

- HuisVeendam reduces their impact on the environment by, among other things, using local materials and recycling.

- In addition, the CO₂ released during the production processes is compensated by working with materials that absorb and store CO₂, such as cattail.

Good to know

The lifespan of Biolaminate strongly depends on the intensity of use. With the current quality, a unit remains usable for at least 36 months.

Growth opportunities

The current market is still focused on conventional flooring such as cheap parquet and linoleum. A handful of pioneers are already laying floors with bio laminate, but it is time that this also became accessible to the construction industry and the average consumer.