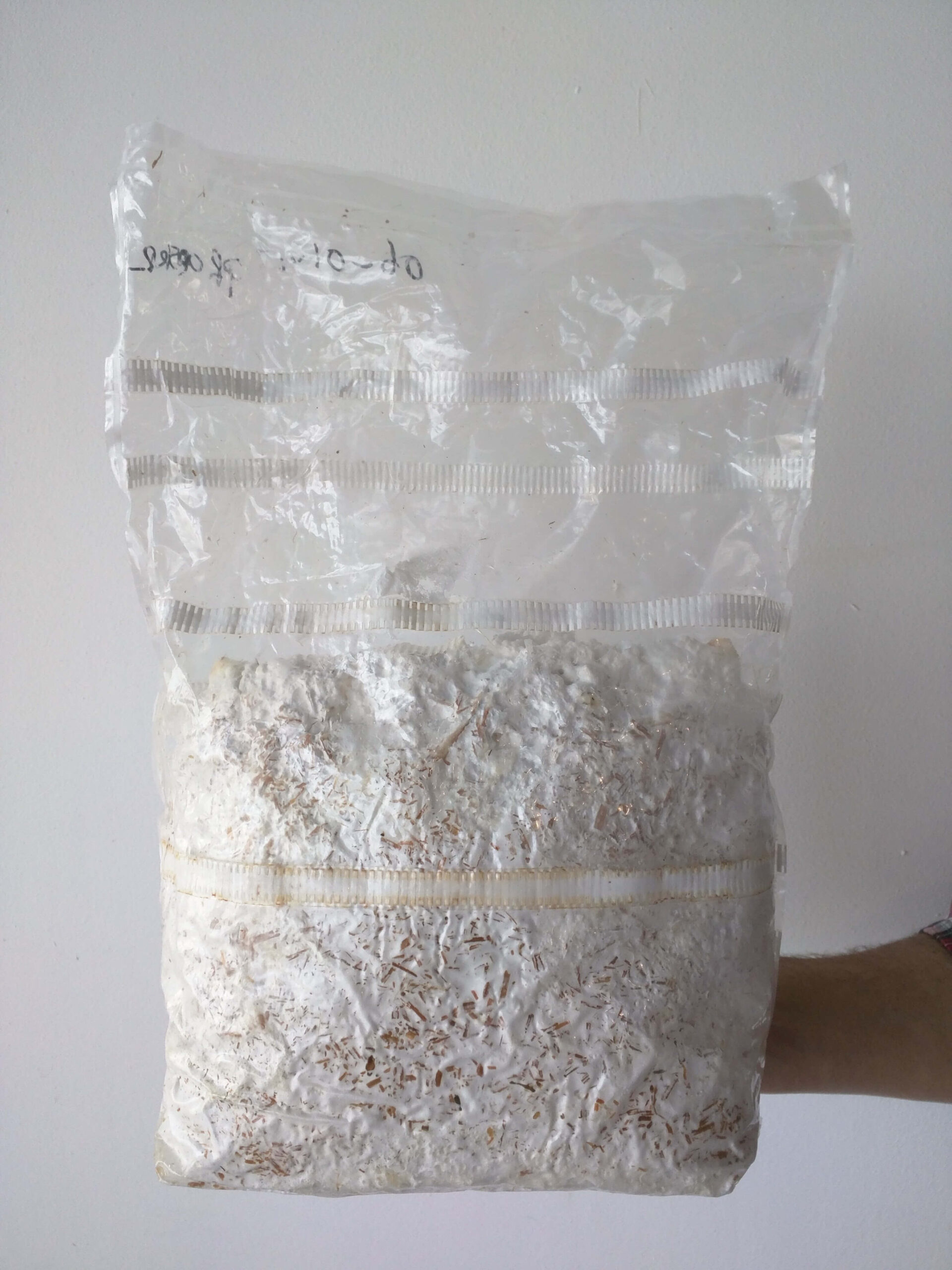

Grown.bio makes products from agricultural waste and mycelium. Also known as mycocomposites, these products are an excellent building material. The material is both temperature insulating as well as acoustically insulating. It can be applied as underflooring or wall cladding. When used outdoors, a proper (biobased) coating is needed.

Grown.bio materials can replace styrofoam and offer a CO2-negative solution to the construction world.

Made of

- Organic waste fibers from the Netherlands, for example hemp from Groningen.

- 10% mycelium (mushroom roots).

Production Process

- The organic waste fibers are mixed and mycelium is added.

- This mixture is put into a pre-shaped mould.

- In the mould, this mixture grows for five days to a rigid shape.

- Finally the product is baked off to kill the mycelium, resulting in a light, strong and 100% biobased product.

Applied

Mycelium based products have many applications. Obviously as a construction material, replacing styrofoam. But besides that, it is also used for packaging or interior products.

Environmental impact

Mycelium-based products are CO2 negative. That works like this:

- The agricultural flows have stored CO2.

- These are then chopped, mixed with mycelium and grown in molds.

- Finally, these are transported to customers.

- These steps result in CO2 emissions, but the CO2 balance is negative because more CO2 is stored in mycelium composites.

Growth opportunities

The market to replace styrofoam is enormous, but to achieve a comparable price point is a challenge. Grown.Bio works hard to increase the production capacity in order to reduce costs.