Concrete is a versatile building material, but it has a significant carbon footprint. Holcim aims to reduce CO2 emissions from concrete production to, ultimately, zero. In addition, Holcim is working on circular construction methods (concrete recycling and alternative fuels).

We use the findings of research into the lifespan and sustainability of concrete for the development of a prefab concrete product that contributes to solving climate challenges. This permeable and vegetated concrete meets technical and ecological requirements of climate adaptation. The vegetated wall reduces heat in the inner city, buffers rainwater, acts as a biofilter, saves valuable space as a vertical garden and promotes biodiversity.

A vegetated wall radiates less heat and allows rainwater to evaporate. This keeps the urban areas cool during extreme heat.

Made of

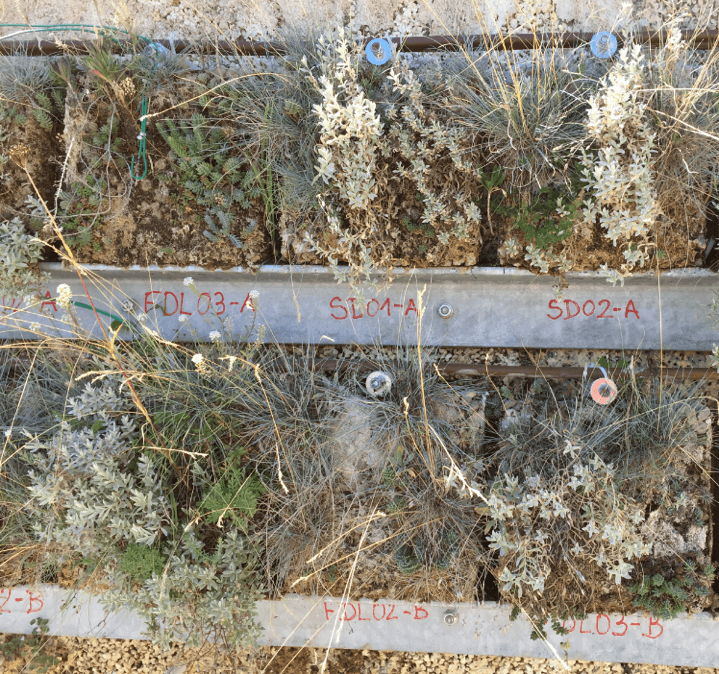

The vegetated wall is composed of two layers. The first layer is a structural concrete layer. The second layer consists of porous concrete (substratum). The composition of the substratum is diverse and can consist of open-pore mineral rocks, recycled materials, and organic matter. The substratum can also consist of the original local soil. The choice of substrate is determined by its water permeability, weight loading, protective effect for the wall, and suitability for the vegetation type. For example, the substrate must be able to retain sufficient water, because it is in this layer that the vegetation emerges.

Production Process

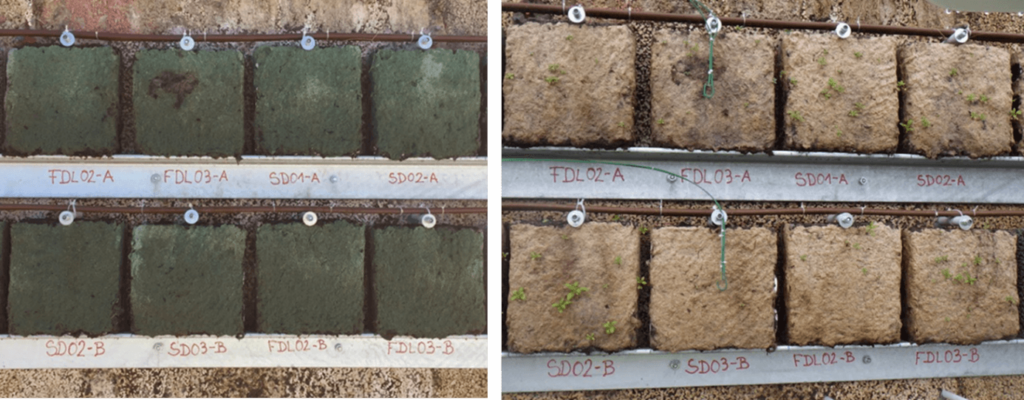

Currently, the vegetated wall is still in the development phase. Tests are being conducted with different types of porous concrete, vegetation and watering.

Applied

The vegetated wall consists of precast concrete elements that can be used in both the (housing) construction and infrastructure sectors. The technology behind it is still under development. Holcim will start with infrastructure projects. Think of applications such as quay walls, noise walls, city parks, bridge piers, transformer houses, retaining walls and airports. Later, this technology will also be applied in (residential) construction, for example to create vertical gardens at houses, apartments, vacation parks, offices, utility buildings and distribution centers.

Environmental impact

With precast concrete you have more control over the production process and you can pour the concrete under optimal conditions and let it cure. Then, under conditioned conditions, you can allow the wall to vegetate. Precast concrete is faster to produce, which can speed up the overall construction process and have less impact on the environment. And with circular construction in mind, let’s not forget that the vegetated wall consists mainly of mineral material, which is ideally suited for circular use.

Good to know

There are many interesting benefits to the vegetated wall, and surely even more to discover. Green walls add tremendous value to the urban environment and to biodiversity. A vegetated wall acts as a biofilter, regulates the temperature of the building and cools the inner city. They also offer benefits acoustically and aesthetically. Vegetated walls retain some of the rainwater, slowing down peak runoff. Vertical gardens also provide valuable space savings, creating unprecedented opportunities. Vegetated walls can help us take groundbreaking steps forward environmentally.

Growth opportunities

Climate change causes all kinds of problems in the urban environment. That is why governments actively pursue an incentive policy for green roofs and walls, with subsidies and tax breaks. At the European level, legislation is increasingly driving the construction of vegetated roofs and walls. Although the Netherlands is still lagging far behind neighboring countries in terms of greening, now that property owners and developers are also beginning to see the benefits, our country will surely soon become greener. It is important that the economic and social advantages of greenery will soon outweigh the additional construction and management costs.