The shade is 3D printed from used fishing nets gathered directly from harbours on the Cornish coast. Repurposing the material helps to keep these ‘ghost nets’ out of the sea.

Discarded fishing nets make up 46% of the Great Pacific Garbage Patch.

Made from

The shade is made from 100% recycled polyamide fishing nets. These nets are sourced from 12 harbours on the Cornish coast of England.

Production Process

- The nets are collected and cleaned.

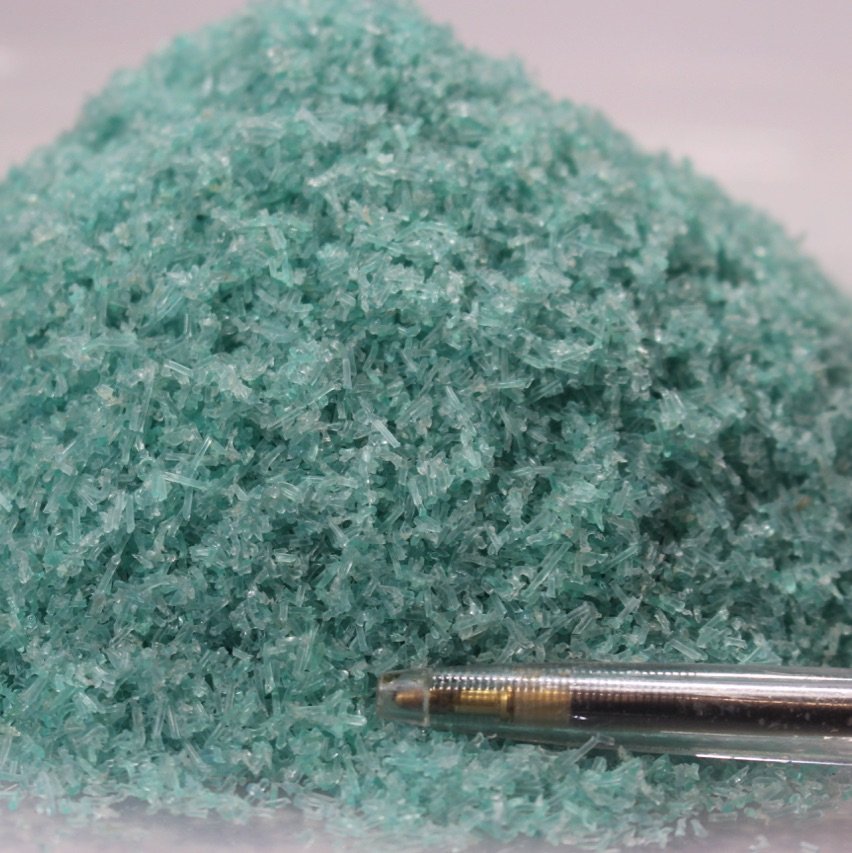

- The nets are chopped and shredded into small pieces.

- This is then extruded into filament, this means that it is processed and transformed into a print-ready material.

- Then Signify uses the filament for 3D printing.

Environmental impact

• By upcycling the fishing nets, they do not end up in the waste mountain

• Upcycling the fishing nets also prevents them from ending up in the sea

• Reduced transport due to printing and assembly in local hubs in Europe

• The lamp is made on demand, so there is no overproduction.

Good to know!

The natural irregularities and translucency create a beautiful gradient light effect when the light is on. Using 3D printing challenged Signify’s normal design process and brought new opportunities to work with recycled materials. Forms and textures are created that are unique for the 3D printing process.

Growth opportunities

The challenge for Signify is in having enough of this particular material. While there are many tons of fishing nets available, they do not all have the translucency and colour of this material. In addition, the machines to process the nets are not yet widespread.