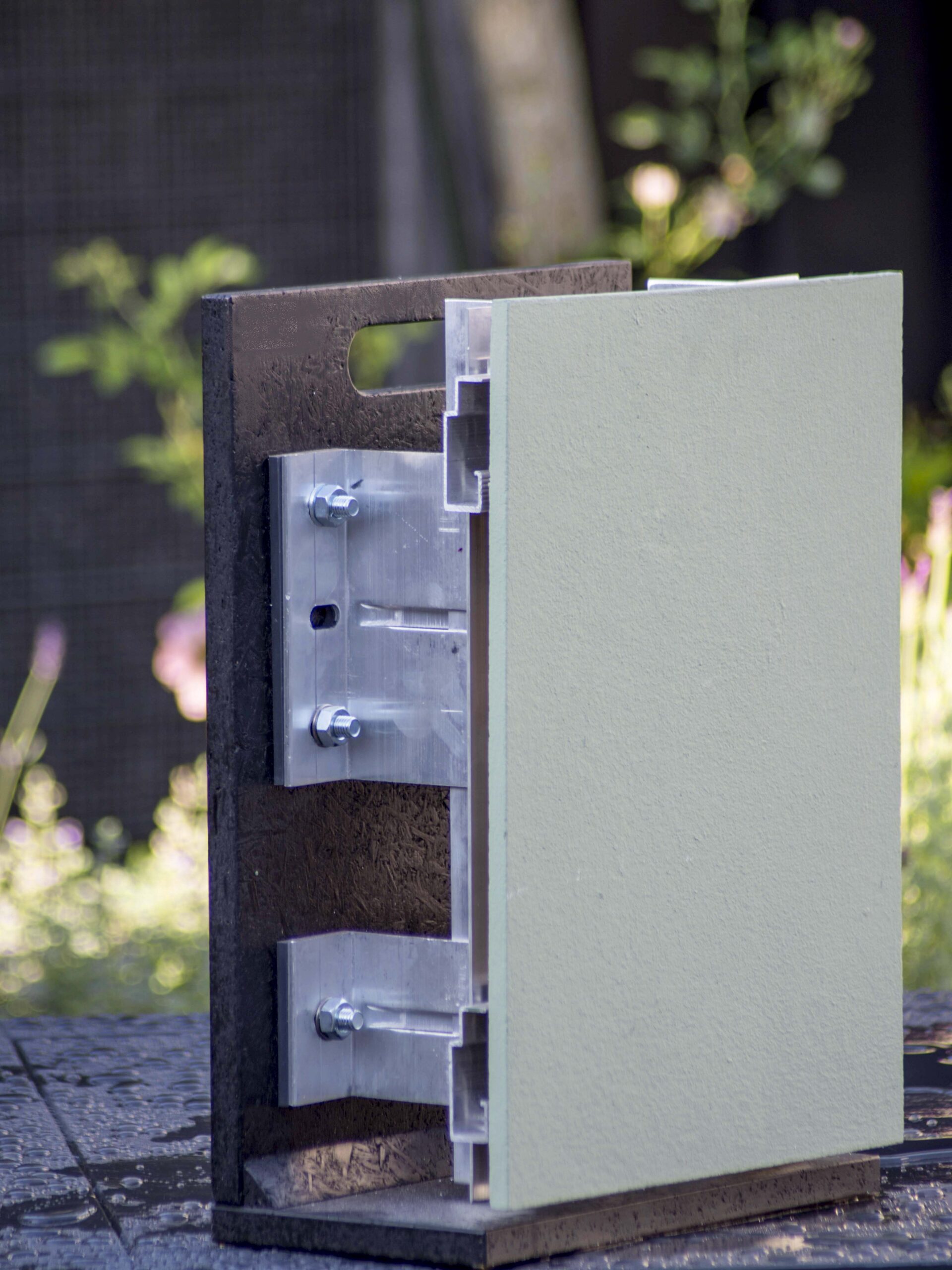

Kerloc is a cold ceramic material that is produced without any additional heating. The material is made of residual materials (Such as natural fibers coming from agriculture, horticulture and / or forestry), minerals and fertilizers. Kerloc is used in the outer shell of a building as facade panels and is 100% circular: it is fully reusable in its own production process.

Cold ground ceramics

The Kerloc facade tiles are made of:

- Natural fibers coming from residual plant materials from agriculture, horticulture and forestry

- Natural minerals

- Fertilizers

Production process

- The residual materials are processed into the right size. The raw materials are mixed in several steps until a homogeneous and usable mixture is obtained

- This ceramic sheet material is produced at normal temperatures through an exothermic reaction. As a result, no ovens are used during this process, ensuring low energy consumption

- The fiber materials are petrified during this process

Applied

Kerloc is applied in the outer shell of a building as facade cladding.

Environmental impact

- Raw materials are locally sourced: most come from The Netherlands or adjacent countries

- All raw materials come from natural (residual) flows

- Kerloc tiles have a long lifespan (over 50 years) and are therefore suited for reassembling

- Fully recyclable in its own production process

Growth opportunities

Kerloc is now KOMO certified. This means it meets the requirements of the Building Decree (falls into the BRL4101 part 11). With a current production capacity of 600,000 m2, Martens ceramics is already able to make Kerloc available on a large scale to interested parties.